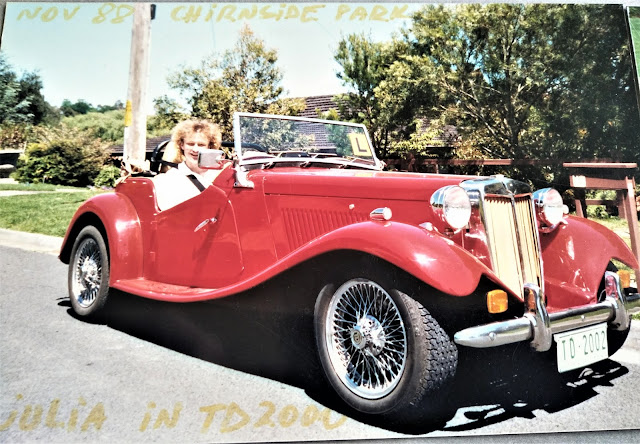

TD2000

was a replica of the British sports car MGTD, with a few modern

features added. The engine was Nissan 2000cc, with Electronic Fuel Injection,

gear box is 5-gear manual (an automatic gearbox was also planned), rear wheels

drive. The chassis was ladder-type, made of steel, body is plastic, leather

seats, instruments modern with „retro“ type dials.

The

idea was born in the company called Marshall Cars in Sydney, N. S. W. Initially

the car had carburetted engine, for volume production an EFI engine was selected. My

job was to design the electrical system and to keep an eye on it during all phases of design, development and production. After a few prototypes the project

was acquired by another company, Geelong Agricultural in the state of Victoria.

Again, after a few prototypes the project was bought by another company

called Australian Classic Cars; it eventually ended up being owned by the Gasons in Ararat, Vic... . I was involved with all the various

prototypes.

Early in 1987 the great number of individual electrical components in the small

space behind instrument panel forced a decision to integrate most of the

components in one „black box“. The design fell to my lap, despite my virtually

zero experience with either electronics or printed circuits design. With the

assistance of several small companies the design was completed in about two

months‘ time. As I was unable to find a manufacturer I decided to

try it myself. I set up a small assembly workshop in our neighbour’s garage,

and produced some 20 of „black boxes“ for the first prototypes. Most of these

were „cobbled up“ from a variety of experimental parts, but most of them

functioned correctly. At the end of prototype run I received a Purchase

Order to produce 400 of the „black boxes“ for the anticipated production of

TD2000 during the next 12 months, with some 1000 units expected to be produced annually thereafter. The Purchase Order marked the beginning of

frantic activity: I had to secure supply of components from several small

companies by issuing my Purchase Orders for them. I was planning to

assemble the modules in my neighbour’s garage, at least initially, but I was

casting around for a suitable workshop for rent. Also, I had to spend

some $50,000 in purchasing of components I needed for the assembly,

components such as enclosures, wiring and connectors assembly and such.

During

months of this frantic activity I failed to notice dark clouds gathering

above the world’s economy; admittedly, a friendly bank manager urged me to

be cautious, but I paid little notice to his fairly nebulous remarks – the

lure of our first $million was too strong...

The

first lightning of the ensuing financial storm hit me just at the time when I was

ready to start volume production: the Purchase Order for delivery of the 400

modules was cancelled! And at the same time Machine Dynamics (an industrial robots manufacturer), where I was still

managing their electrical design and assembly department, declared itself

bankrupt.

The activity which started a few months earlier in one direction,

that of starting the production, repeated itself in the opposite direction –

how to stop it. I had to cancel the number of Purchase Orders I issued

to my suppliers; had to stop the still ongoing design of details of production;

had to dismantle the little workshop in the neighbour’s garage; had to pay

those few people who worked for me on subcontract at the Machine Dynamics; and

had to dispose of the number of components already purchased – most of them

sold at a huge loss (the time of financial crisis is ideal for buying, not for selling!)...

As

for myself, I lost my income from Machine Dynamics and was at the bottom

financially – and without work! I applied for Unemployment Benefit, the

meagre sum of which represented but some 20% of my income to date, and started

searching for new contract. The contract came in about two months‘ time in the

form of offer to work as an electrical engineer for Mitsubishi Motors in Adelaide, which offer I gladly

accepted.

Looking back I realised

that I should have paid much more attention to the economic climate in the

country and the world, but I have my doubts whether I would have

acted any differently – who in the world is able to predict the World’s Economy

Crisis (except for those who are in the position to kick it off)?

No comments:

Post a Comment